Pressure Intensifiers

Reciprocating or single-stroke cylinder intensifiers are used to increase the pressure output of an existing low-pressure system, giving a boost of pressure when and where it’s needed, yielding greater pressure.

BROWSE BY CATEGORY

Pressure Intensifiers

Without a doubt, hydraulic solutions can be said to operate with immense force. Whoever occasionally needs even more force, albeit for only a brief spell and therefore does not want to reconfigure the complete hydraulic system to suit, can now save themselves the bother, if they opt to install a pressure intensifier. A hydraulic pressure intensifier can be used for many applications: rupture tests on hoses, pipes and containers, hydroforming, bolt tensioning, presses, proportioning precisely defined volumes, demolition tools including stone crushing tools and hydraulic construction tools, hydraulic power packs, and workholding swing cylinders.

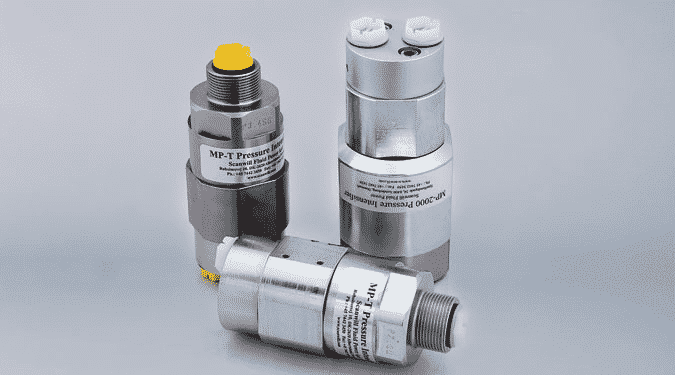

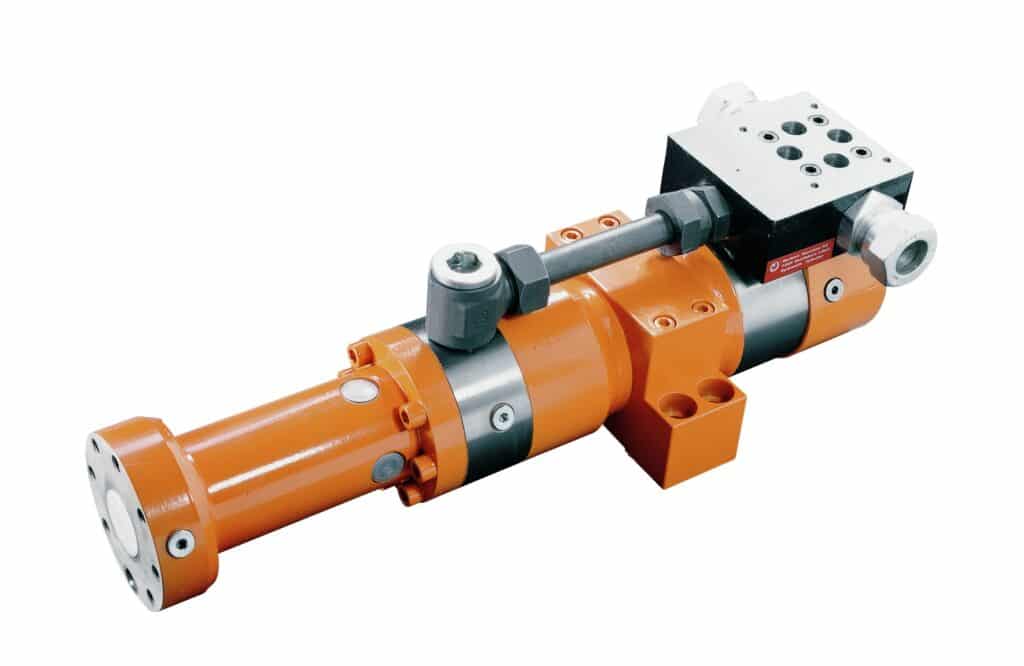

Reciprocating Type

Hydraulic Tool Intensifier

Single-Stroke Cylinder Type

How do Pressure Intensifiers Work?

Pressure intensifiers are powered by a pump, which is operating at a set pressure. The hydraulic intensifier consistently delivers flow until the output pressure has been reached. The flow from the pump enters the intensifier, where two pistons of different size (respective to the intensification ratio) pump the fluid thereby intensifying it. In the process, waste flow is returned to tank.

How are Pressure Intensifiers Used?

Hydraulic intensifiers were first seen in CNC machines in the workholding industry. Today, hydraulic intensifiers are frequently used in hydraulic power packs as a cost-efficient way to generate high pressure, without having to purchase a high-pressure system.

In What Applications are Pressure Intensifiers Used?

A hydraulic pressure intensifier can be used for many applications, such as rupture tests on hoses, pipes, and containers; hydroforming; bolt tensioning; presses; proportioning precisely defined volumes; demolition tools including stone crushing tools and hydraulic construction tools; hydraulic power packs; and workholding cylinders.

What are the Benefits of a Pressure Intensifier?

Hydraulic intensifiers are a fast and cost-effective solution to increasing pressure in comparison to other alternatives, such as replacing and buying a new hydraulic power pack or HPU. Its compact design features a built-in bypass valve and POV and allows for a simple and quick installation.

Pressure intensifiers are offered in a range of options, such as in-line models that are designed to fit standard industry pipe clamps. Intensifiers can also come in flange-on models, cetop models, and as cartridge-type intensifiers.

What is the Flow and Pressure Rate of Hydraulic Pressure Intensifiers?

Pressure intensifiers are selected by choosing the intensification ratio (the multiplication factor from your input pressure to your required output pressure), flow rate, pressure, and mounting requirements for your applications. Hydraulic intensifiers can have a flow rate starting at 0.3 gpm/1.1 lpm and up to 21 gpm/79.4 lpm depending on the model. In terms of pressure, hydraulic intensifiers typically produce between 1,000 to 7,300 psi. Some models have the capacity to generate between 20,000 to 60,000 psi.

Hydraulic pressure intensifiers provide standard intensification ratios of up to 16 and yield maximum outlet pressures of 58,000 psi / 4,000 bar. Hydraulic pressure intensifiers supply maximum inlet flow rates of 21.16 GPM / 80 LPM. IC-Fluid Power offers 12 different series which are selected by the required inlet and outlet pressure in combination with flow rates. Custom configurations available.