10,000 PSI Valves

Manual Valves, Directional Control Valves, and Relief Valves for 10,000 psi (700 bar)

BROWSE BY CATEGORY

10,000 PSI Valves

Manual Valves, Directional Control Valves, and Relief Valves for 10,000 psi (700 bar).

Manual Valves, Directional Control Valves, and Relief Valves for 10,000 psi (700 bar)

Manual Valves, Directional Control Valves, and Relief Valves for 10,000 psi (700 bar).

Introducing a new generation of servo valves that deliver exceptional performance and precision, without compromise to cost, efficiency, and industrial reliability.

World’s smallest direct drive valve weighing less than 0.64 lbs (300 g), flow up to 5 gpm (18 lpm).

Ultimate power density weighing 1.21 lbs (550 g) with flow up to 16 gpm (60 lpm).

Most efficient direct drive valve for high flow applications from 13 to 66 gpm (50 to 250 lpm).

The next evolution in high-performance, high-flow valves from 66-174 gpm (250-660 lpm).

Patented additive manufacturing and compact electronics create new standards in power density, performance, and reliability.

78% faster step response than traditional two stage valves with low hysteresis, null shift and threshold.

$400 in annual energy savings per valve compared to a typical two stage valve.

Two-stage servo valves, or mechanical feedback valves, are valued for their compact size and excellent dynamic performance, including fast response times and high-frequency capabilities. However, they come with limitations. The small orifices and high-pressure seals that help maintain performance can also make them more susceptible to contamination and blockages, especially if operated in harsh environments. Additionally, because they lack onboard electronics, they do not deliver the same level of repeatability and accuracy as modern direct drive valves.

Direct drive valves utilize an electrical feedback design. Contamination and hysteresis occur less frequently with direct drive valves making them more durable for demanding industrial applications. However, this comes with trade-offs in performance and size. Direct drive valves are generally heavier and bulkier in design, with slower step and frequency responses compared to two-step valves. This makes them less suitable for high-performance applications where dynamic response is critical.

A Domin valve is a considered a servo proportional valve, a hybrid between two-stage servo valves and direct drive valves. Domin merges the benefits, such as the performance, efficiency, precision, and compact size from both without needing to compromise. Domin’s S6 Pro, for instance, offers an unmatched balance of performance and efficiency, boasting a 78% lighter design, a 67% faster response, 340% higher bandwidth, and 73% higher maximum flow compared to an equivalent direct drive valve.

Slim, on-board electronics replace outdated bulky centralized systems. This improves control, data processing, and communication capabilities while reducing the overall size.

Modern design and simulation technologies streamline development, enabling rapid iterations and faster decision-making and production processes.

Hall effect sensors provide a more efficient and precise method of measuring position compared to traditional linear transducers. By utilizing magnetic fields, these sensors offer exceptional accuracy in both linear and rotary applications while significantly reducing size and weight.

Domin valves are equipped with brushless DC motors, offering superior precision and efficiency over traditional solenoids and limited-angle torque motors. These motors provide consistent performance without the wear issues associated with brushes, leading to longer life and reduced maintenance.

This patented manufacturing process surpasses the limitations of subtractive machining, allowing the creation of lightweight structures through optimized material distribution and the removal of excess material.

First, choose the appropriate valve for your application. Domin valves have been designed to accommodate a wide range of flow rates and pressure conditions. The options include:

Next choose rated flow. Flow range is between 0.2 to 66 gpm (0.5 to 250 lpm), all rated at a 1,015 psi (70 bar) pressure drop. For systems requiring high precision control, the rated flow can be tuned to the nearest decimal point within the range for near-exact performance.

The spool lap condition determines how the valve reacts to control inputs.

Standard spool lap conditions:

Domin valves feature electrical feedback and onboard electronics to simplify integration into modern hydraulic systems. All that is needed is a 24V power supply and a standard input/output interface. The control method options allow for seamless integration with various control architectures, ensuring that the valve response precisely to electrical signals.

Control method options:

Next, select the right connector. Industry-standard connectors are provided to ensure easy compatibility and simple integration with your existing infrastructure.

Common connector options:

For systems requiring an enable mode, typically a simple yes or no option, these can be easily configured into the Domin valve.

This feature allows operators to control when the valve is active, improving both safety and flexibility.

Domin valves operate with standard red oil, as it is the most common fluid type found in hydraulic systems. Custom solutions are available for specialized fluid requirements.

Selecting the right seal material ensures that the valve operates properly, even in harsh and challenging environments.

Seal options:

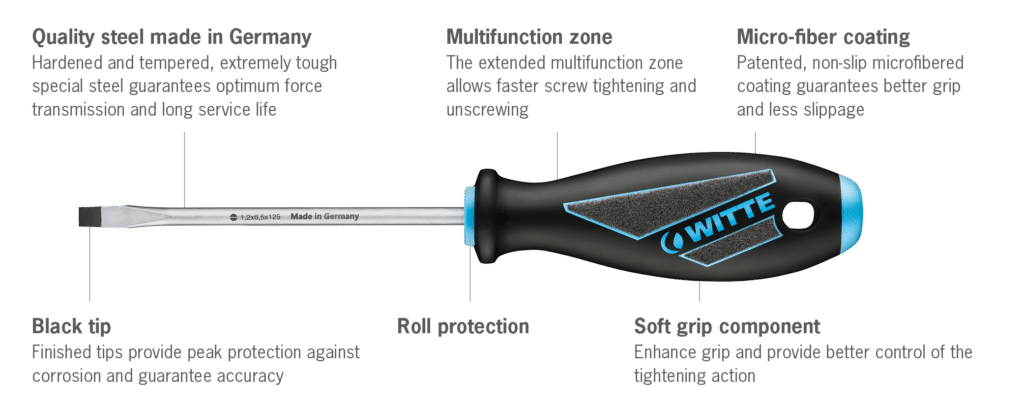

Witte has continuously perfected the screwdriver like no other manufacturer – with the aid of unrelenting innovation, maximum attention to ergonomic design, as well as high quality materials made in Germany. Shape, hand-picked materials, ergonomic design, workmanship and physics all combine here to make the perfect tool.

We offer the option to return any product at your discretion at any time. Rest assured, your product will be replaced with no explanations needed with complementary shipping, free of charge.

Flexible sales and branding concepts make it possible for us to supply individual packaging and designs for distributors or OEMs.

Witte Max Screwdrivers have been extensively tested by the Independent IGR Institute for Health and Ergonomics with regard to usability and ergonomics.

Equipped with a patented, slip-resistant flocked, micro-fibered surface panels, the MAXX Plus screwdriver is the perfect tool for working in oily and wet conditions.

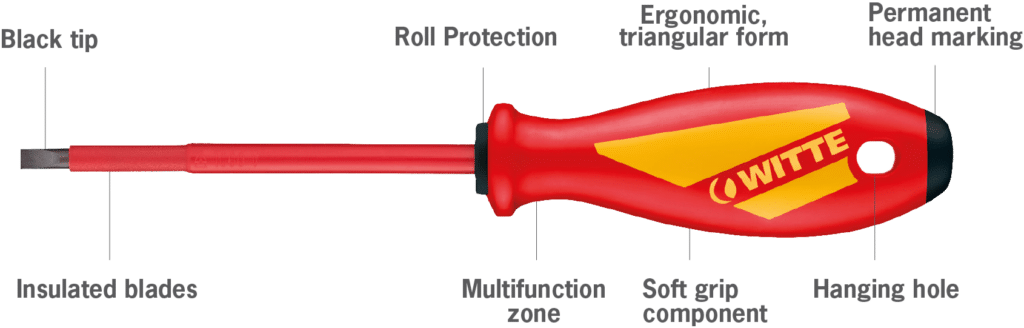

Ensuring peak accuracy at the point of contact with the screw — even at voltages up to 1000 volts, because every screwdriver is tested in a dip-tank up to 10,000 volts.

Ergonomic, force and safety – the MAXX VDE gets best results in all disciplines. It is tested individually in a water bath at 10,000 volts which enables it to work with voltages of up to 1,000.

Check valves block an oil flow in one direction and allow it in the other direction. They are a type of shutoff valve. The check valve is inserted when an oil flow shall be allowed in one direction only. Meanwhile, the usage of check valves prevents backflow of the fluid.

Advantages at a Glance:

The HYTORC-check valves are available with a screw-in or caged design. Even so, both designs can be obtained in two flow directions: with the screw-in direction closed or with free-flow. The spherical cap remains reliably tight in every position, in case of multiple switching cycles and under severe stress.

The HYTORC check valve easily screws into a regular hole (Dimensions screw-in drill). The screw-in check valves are sealed through an edge sealing which is turned to the cage. The edge sealing, together with the drill draft, forms a gap-free chamber for the O-Ring. The gap-free chamber and the O-Ring are repeatable sealing.

The valve is made of a high-strength hardened steel. Moreover, the ball seat is specially treated and the spherical shell is manufactured with a high tensile hardened and polished ball bearing ball. Thus, the design of the check valves is compact and economical which saves space and offers simple installation.

Hytorc-HydroWer is a supplier and power unit accessory and valve manufacturer for various applications including construction, mechanical, marine, and industrial.

Pressure is one of the most important diagnostic parameters in the hydraulic circuit. Obtaining pressure readings is essential to successful preventive maintenance and troubleshooting. The Spradow test points allow the connection of a pressure gauge in only seconds while the equipment is running. It is the safest, cleanest and most convenient way of measuring pressure. Designing your equipment with the Spradow test points will improve the quality of your equipment and in today’s market, higher quality makes the equipment more attractive to potential buyers. The spring loaded check valve inside the test point opens during engagement of the special micro-bore hose fitting end. The connection can be performed under pressure without the use of tools. A single gauge connected to the high pressure micro-bore hose can check an unlimited number of test points. We also offer various types of hose assemblies for direct connection to the test fitting.

Spradow is a supplier and test point and test hose assembly manufacturer for various applications including construction, mechanical, technological, and industrial.

The Hytorc butterfly valve is a component designed to save time for the technician working on the hydraulic system by not having to drain the reservoir. The valve is designed for low pressure hydraulic lines up to 230 psi and can be installed into the pump suction line or mounted directly on to the hydraulic reservoir for example. The maximum pressure differential on either side of the valve should not exceed 58 psi when the valve is closed.

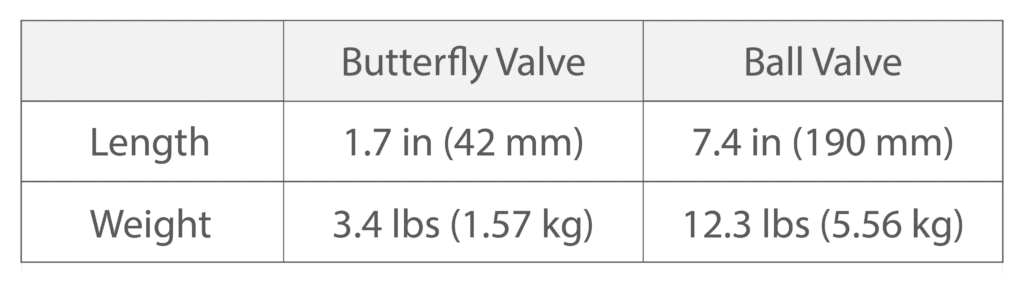

For a 4″ pipe, butterfly valves are nearly 77% shorter and 71% lighter than a ball valve of the same diameter.

In applications where fitting ball valves into the design poses a challenge, butterfly valves provide an effective solution. These valves are significantly shorter and lighter than their counterparts, facilitating easier handling and installation. The advantages of this design become increasingly evident as the nominal diameter rises. This is particularly beneficial in mobile hydraulics where space is a premium.

Thanks to internal clamping bolts, the valve is tightly secured to the reservoir even when even when disconnecting pipes or flexible connectors. This design enables maintenance without draining the reservoir.

Shut off valves can be fitted between flanges due to the lateral recesses. Alternatively, heavy suction pipes can be held with additional screws.

The valve’s inner diameter is larger than the pipe, enabling full flow capacity without compromising on oil volume. This feature is crucial for maintaining efficient and precise control.

The self-engaging lock bar provides a secure and stable connection. The lock bar automatically engages in all switch positions; fully open, closed, or at an intermediate position, and ensures arresting of the valve’s position even without a shift lever.

Prevent damage to your pump by making sure the valve is open prior to turning on the pump.

Hytorc-HydroWer is a supplier and power unit accessory and valve manufacturer for various applications including construction, mechanical, marine, and industrial.

The HydroWer Rubber Compensator is a product that qualifies as one of the best kept secrets of power unit accessories. The compensators are flexible connectors with SAE or DIN flanges that correct pipe alignment problems. They also provide a benefit with damping of vibrations, noises and movements in axial and transverse direction.

The HydroWer Compensator is constructed of an inner liner of a reinforced high strength nitrile rubber (Perbunan). The outer and inside layers are smooth and have an aerodynamic design that eliminates cavitation. Both ends have a vulcanized sealing surface, eliminating the need of additional seals. The maximum operating pressure is 115 psi from -4 °F to +176 °F

Hytorc-HydroWer is a supplier and power unit accessory and valve manufacturer for various applications including construction, mechanical, marine, and industrial.

The Serv-Clip® tube measuring connection is used to add a test point on an existing hydraulic circuit within 3 minutes—no cutting of pipes, even if the system is pressurized to 9,100 psi (630 bar). Then carry out your measurements: pressure, flow rate, leakage, temperature, oil sampling or connect a variety of measuring devices.

Required tools for installation: 6mm allen wrench and jaw wrench SW22

Models: Serv-Clip® Type 1 (Installation on pressurized pipes):

Used for sensors with G1/4″ thread

Serv-Clip® Type 2 (Installation on non-pressurized pipes):

Used for sensors with G3/8″ thread

The flow rate and leakage sensor functions through the calorimetric principle and can be installed with the Serv-Clip tube measuring connection Serv-Clip® (type 2) in 5 Minutes without cutting pipelines and only requiring the pressure of the hydraulic system to be removed while the needle is piercing the pipe or tube and while the sensor is being installed. The output signal is 4 to 20mA and is calibrated according to your requirements. With the Flow Rate Sensor (from 0.164 to 16.4 feet per second or from 0.05 to 5 meters per second). The sensors are available in stainless steel and plastic covers:

With the Leakage sensor (from 0.164 to 16.4 feet per second or from 0.05 to 5 meters per second):

Watch the following videos for a demonstration of how the Serv-Clip is installed and utilized.

Serv-Clip® is a supplier and Serv-Clip® Hot Tap Connection manufacturer for various applications including construction, mechanical, technological, and industrial.

A compact and high-torque way to open and close your valves, increasing performance, uptime, reliability, and safety while reducing maintenance costs using helical spline technology.

Valve actuators mount on valves and move valves to a desired position by utilizing liquid, electric or some other power source. Selecting the correct valve actuator will increase performance, uptime, reliability, and safety while reducing maintenance costs. Although the most common and important use of an valve actuator is to open and close valves, current actuator designs go far beyond the basic open and close function. The valve actuator can be packaged together with position sensing equipment, torque sensing, motor protection, logic control and digital communication capacity all in a compact, protected enclosure. Applications include: power plants, oil and gas, industrial, ships and chemical industries. Below is a listing of valve actuators available from IC-Fluid Power.

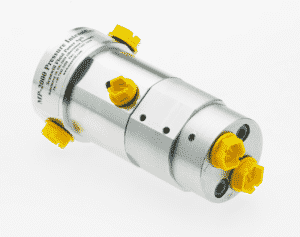

Compact yet powerful, pressure intensifiers deliver a nearly instant pressure boost precisely when and where it’s required.

Hydraulic pressure intensifiers provide standard intensification ratios of up to 16 and yield maximum outlet pressures of 58,000 psi / 4,000 bar.

A tool intensifier is a safety device that intensifies the available pressure from your truck to power your 10,000 psi hydraulic tools.

Single-Stroke Cylinder Type pressure intensifiers allow the input fluid to be the same as, or different than, the output fluid.

Increase output pressure from a low-pressure supply without major investments or upgrades.

Add pressure only where and when needed. Using low-pressure components with an intensifier cuts down on operating costs.

1-2 week lead times, so that you can work faster. For cases with higher urgency, faster delivery may be possible.

Reciprocating or single-stroke cylinder intensifiers are used to increase the pressure output of an existing low-pressure system, giving a boost of pressure when and where it’s needed, yielding greater pressure.

Pressure intensifiers are powered by a pump, which is operating at a set pressure. The hydraulic intensifier consistently delivers flow until the output pressure has been reached. The flow from the pump enters the intensifier, where two pistons of different sizes (respective to the intensification ratio) pump the fluid, thereby intensifying it. In the process, waste flow is returned to the tank.

A hydraulic pressure intensifier can be used for many applications. These include rupture tests on hoses, pipes, and containers; hydroforming; bolt tensioning; presses; and proportioning precisely defined volumes. It is also useful for demolition tools, such as stone crushing tools and hydraulic construction tools. Additionally, it can be employed in hydraulic power packs and workholding cylinders.

In mobile applications, such as cranes, pressure intensifiers increase the pressure in the cylinders during retraction and ensure sufficient pressure within the stabilizer. The outlet pressures for this application include 3625 psi/250bar – 4350 psi/300 bar.

Pressure intensifiers can be used to provide test pressures for hydraulic components at 7250 psi/500 bar – 11,600 psi/800 bar, and for tubes and hoses for diesel engines (2,000+ bar). Pressure can be boosted from existing HPUs to negate having to buy an additional test pump.

Power hydraulic tools with a pressure intensifier connected to an existing power source. Intensifiers can boost pump pressure from as low as 1,450 psi/100 bar to an operational range of 4,350 psi/300 bar – 11,600 psi/800 bar.